Reseamα

About Reseamα

Reseamαis a biomass plastic manufactured by blending corn starch.

Can reduce petroleum usage and deal with various molding method.

Gelatinization is a key process of Reseamα.

This key process will expand range of usage different from Reseam ST.

A biomass bag excellent in printability.

Soft and smooth texture with printability, has a certification of Food sanitation act in Japan (Ministry of Health, Labor and Welfare notification No.370)

Natural Semitransparent biomass bottle

Natural coloring of the original resin. Can check the remaining amount and color of the content.

Reseamα Features

- Semitransparent

- Printing suitability

- Soft and smooth texture

- Thinnest 20μm or less is possible.

About

Gelatinization

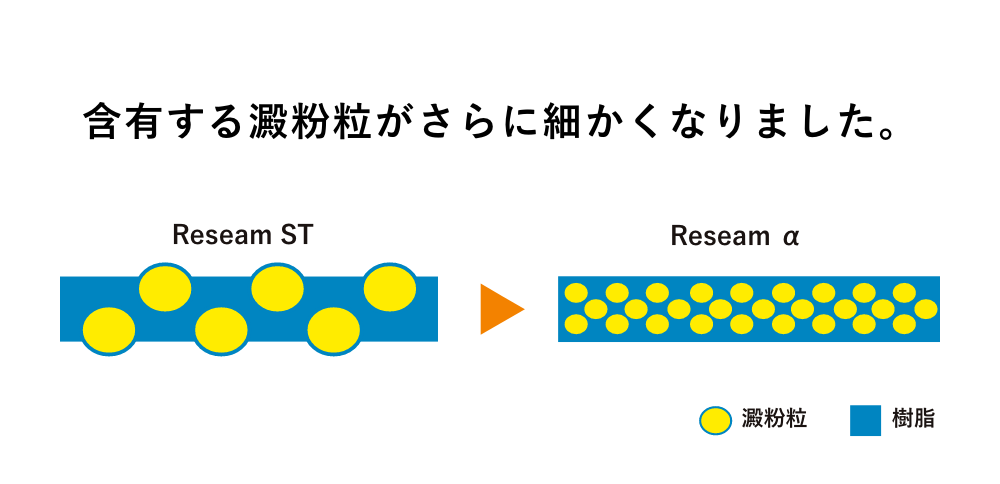

- Make starch grain smaller like mash rice into glue. By doing this manufacturing process, Reseamαcan get different feature from Reseam ST. Main features are as follows. Thin film molding become possible because Elongation during molding is improved. Improves printing suitability because of Reduction of surface irregularities

Development

Products

Sheet molding and non-woven fabric molding will also possible by feature of gelatinization.

PRODUCTS

-

Reseamα

Gelatinization is a key process of Reseam α. This key process will expand range of usage different from Reseam ST. Deal with various molding methods.

-

Pireeru®

A biomass sealant film by blending corn starch. It can laminate various base material together and change characteristic from it.

-

Others

KOBAYASHI has a Technical Research Laboratory in Chiba, which keep researching to develop new materials for customer’s demand.